Fundamentals of Aluminum Foundries: Key Information You Should Know

Understanding the essentials of aluminum foundry operations is vital for any individual engaged in manufacturing. This includes understanding the complexities of the casting process, identifying the diverse mold types, and following safety protocols. Each individual aspect plays a vital role in ensuring quality and efficiency. As industries continually rely on aluminum castings, familiarizing oneself with these basics can lead to substantial advantages. What specific elements make up the aluminum casting process?

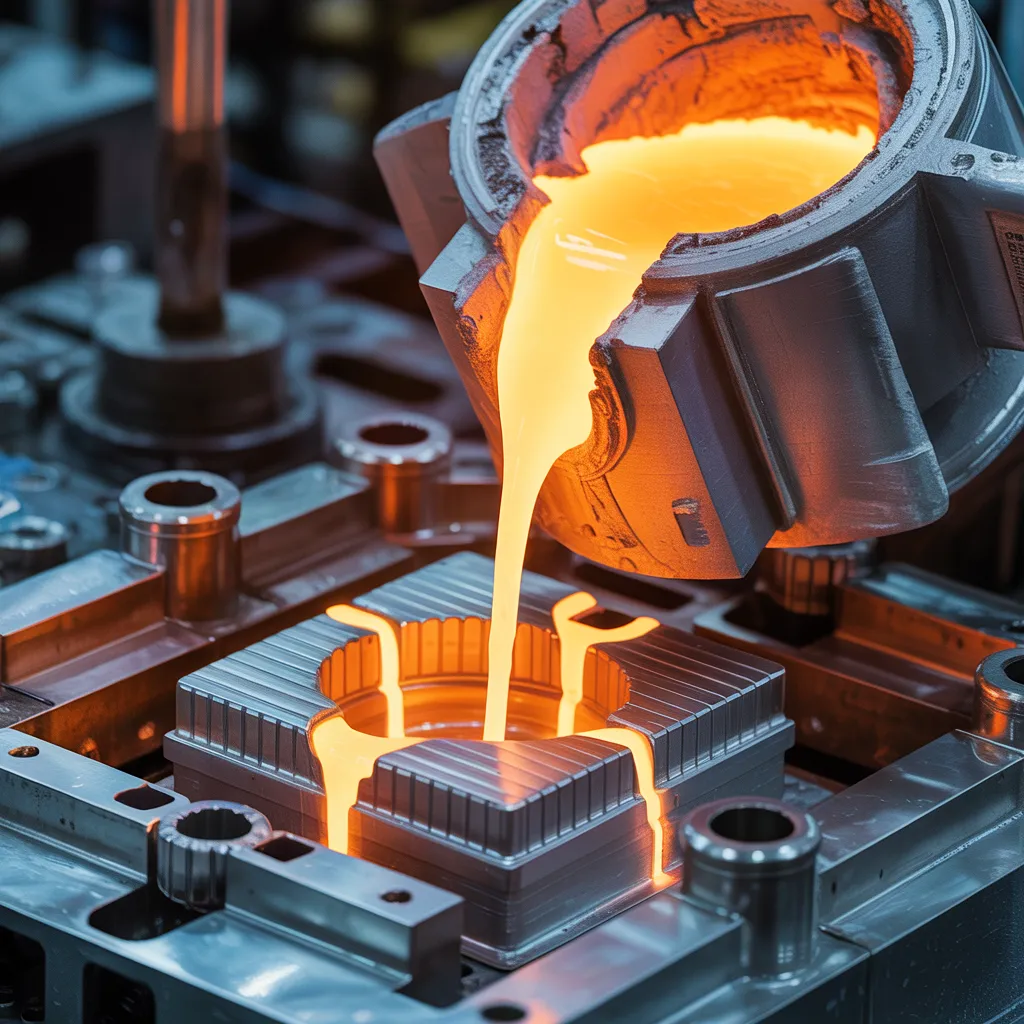

Step-by-Step Aluminum Casting Process

The process of aluminum casting typically encompasses multiple essential stages that change raw aluminum into finished products. Initially, the process begins with melting the aluminum, which is generally carried out in a furnace. The liquefied aluminum is then deposited into molds designed to shape the final product. These molds can be created from different materials, including sand or metal, according to the production requirements.

When the aluminum has cooled down and solidified within the mold, the next step is to take out the casting. This is typically achieved by breaking the mold or using mechanical methods. Upon removal, the casting experiences various finishing procedures, which may include trimming extra material, grinding, and polishing to attain the desired surface quality.

Finally, quality control checks are performed to validate the components fulfill specified standards. This step is crucial in ensuring that the final products are adequate for their intended applications in multiple industries.

Properties of Aluminum

Aluminum features a distinctive combination of qualities that make it a highly sought-after material in diverse industries. Its lightweight property, with a density approximately one-third that of steel, enables ease of handling and improves fuel efficiency in transportation applications. In addition, aluminum displays excellent corrosion resistance resulting from the formation of a protective oxide layer, extending its lifespan in multiple environments.

The material is also known for its impressive strength-to-weight ratio, permitting the creation of strong yet lightweight structures. Furthermore, aluminum is very malleable and ductile, thus making it suitable for numerous manufacturing processes, including casting, extrusion, and machining.

Thermal and electrical conductivity are other notable characteristics, encouraging its use in electrical components and heat exchangers. Furthermore, aluminum is entirely recyclable without losing quality, aligning with sustainable practices and decreasing environmental impact in industries that utilize it.

Categories of Molds in Aluminum Foundries

In aluminum foundries, various types of molds are employed to achieve different casting techniques and product specifications. The most prevalent mold varieties include sand molds, which enable detailed designs and are frequently employed for custom or small-batch production. Permanent molds, usually constructed from metal, are utilized for mass production and offer enhanced dimensional accuracy and finish. Ceramic-coated wax pattern molds used in investment casting are excellent for complex forms with delicate features. Additionally, shell molds, which consist of a thin shell of sand and resin, offer excellent surface finish and are suitable for medium production runs. Each mold category presents specific advantages and is selected depending on elements such as manufacturing volume, component complexity, and target finish. Comprehending these mold choices is essential for obtaining optimal outcomes in aluminum casting operations.

Essential Equipment for Aluminum Foundry Excellence

Successful aluminum foundries need specific equipment to guarantee efficient operations. Key components include melting furnaces for material processing, molds and patterns for shaping, and essential safety gear to protect workers. Understanding and investing in these must-have items is vital for achieving optimal results in aluminum casting.

Critical Melting Furnace Basics

When creating a successful aluminum foundry, choosing the right melting furnace is crucial, as it directly influences the quality of the final product. Important factors include furnace type, capacity, and energy efficiency. Standard types of melting furnaces include crucible, induction, and reverberatory, each delivering distinct advantages for different production scales. The furnace capacity must align with the foundry's production requirements to guarantee timely processing. Additionally, energy efficiency is vital for minimizing operational costs. Proper temperature control is vital for achieving consistent melt quality and preventing contamination. Investing in reliable refractory materials increases furnace durability and thermal efficiency. Finally, the right melting furnace contributes markedly to the foundry's overall performance and product integrity.

Patterns and Molds

Molds and patterns function as the foundation of aluminum foundry operations, directly impacting the accuracy and quality of castings. These tools are vital for shaping the desired shapes and dimensions of the final product. Patterns, usually made from plastic, metal, or wood, are used to produce molds that retain the molten aluminum until it solidifies. The choice of material influences the mold's durability and heat resistance. Moreover, the design of molds must consider factors like shrinkage and ease of removal, ensuring high-quality outputs. Foundries commonly utilize multiple mold types, such as sand molds and permanent molds, depending on production demands. Understanding the complexities of molds and patterns is essential for achieving effective casting results in aluminum foundry operations.

Safety Equipment Requirements

In aluminum foundry facilities, safety gear protocols are essential to protect workers from the inherent risks related to molten metal and heavy machinery. Essential safety equipment includes high-temperature gloves to avoid burn injuries, safety goggles to shield eyes from flying debris, and face shields to guard against splashes of molten metal. Workers need to wear flame-resistant attire and steel-toed boots to protect from heavy objects and heat exposure. Furthermore, ear protection is crucial due to the loud noise levels created by machinery. Appropriate respiratory gear may be needed to avoid inhaling harmful fumes. Following these safety gear requirements not only guarantees worker safety but also promotes a more effective and streamlined foundry operation.

Safety Practices in Aluminum Casting

In aluminum casting, safety practices are essential to protect workers from potential hazards. Key components include the use of personal protective equipment, ensuring adequate ventilation, and establishing emergency response procedures. These protocols collectively establish a more protected work environment in the foundry.

Individual Protective Equipment

A complete grasp of personal protective equipment (PPE) is critical for securing safety in aluminum casting operations. Appropriate PPE includes thermal-protective gloves, face shields, and safety goggles to guard against molten metal splashes and heat exposure. Workers should also wear flame-retardant clothing and steel-toed boots to decrease injury risks from heavy equipment and hot materials. Respirators may be necessary to guard against harmful dust and fumes produced during the casting process. Additionally, hearing protection is recommended due to high noise levels in foundry environments. Routine inspection and maintenance of PPE are imperative to confirm effectiveness. By observing these safety practices, workers can significantly reduce the risk of accidents and injuries, fostering a safer workplace for all involved in aluminum casting.

Ventilation Needs

Proper ventilation is a critical component in guaranteeing safety within aluminum casting operations. Proper airflow minimizes the collection of dangerous fumes and dust generated during the melting and pouring processes. It is crucial to design ventilation systems that efficiently exchange indoor air with fresh outdoor air, sustaining safe breathable conditions. Local exhaust ventilation systems should be placed near sources of pollutants to capture them at the source. Additionally, air monitoring systems can help evaluate air quality, maintaining compliance with occupational health standards. Regular maintenance and inspection of ventilation equipment are critical to ensure optimal performance. By prioritizing proper ventilation, foundries can notably reduce the risks connected with air contaminants, creating a safer working environment for all employees involved in aluminum casting.

Crisis Response Procedures

Preparedness is essential in aluminum casting operations, where the potential for accidents requires well-defined emergency response procedures. Establishing a clear plan is crucial for safeguarding employees and minimizing damage. Key elements of these procedures include identifying emergency exits, ensuring accessible first aid kits, and conducting regular safety drills. Employees must be trained to spot potential hazards, such as molten metal spills and equipment malfunctions, and know how to act appropriately. Communication protocols should be set up, allowing for prompt reporting of incidents. Furthermore, designated personnel should be assigned to lead emergency responses, ensuring a coordinated effort. Regular reviews and updates of these procedures are critical to adapt to any changes in operations or equipment. Safety is the responsibility of all personnel in the foundry environment.

Leading Industries Working with Aluminum Castings

Aluminum castings fulfill a critical purpose in multiple industrial fields, demonstrating their adaptability and durability. The automotive field is a major consumer of aluminum castings, employing them for motor blocks, transmission enclosures, and wheels. Their lightweight nature contributes to enhanced fuel efficiency and performance. The aerospace industry also takes advantage of aluminum castings, where components are fabricated to endure extreme conditions while reducing weight. Furthermore, the electronics sector uses aluminum castings for enclosures and heat sinks, providing optimal thermal management in devices. In construction, aluminum castings are employed in window frames, railings, and support structures, offering longevity and resistance to corrosion. Furthermore, the consumer goods industry employs aluminum castings for numerous products, from cookware to furniture, emphasizing their design qualities and functional properties. Overall, the flexibility of aluminum castings makes them crucial in numerous industries, improving product performance and longevity.

FAQ

What Environmental Effects Do Aluminum Foundries Have?

Aluminum foundries contribute to environmental impacts through waste generation, energy consumption, and greenhouse gas emissions. Moreover, they can emit particulate matter and other pollutants, potentially affecting air quality and surrounding ecosystems if not adequately controlled.

How Can I Start My Own Aluminum Foundry?

To establish an aluminum foundry, one must carry out market research, acquire financing, acquire necessary permits, choose proper machinery, and establish a skilled workforce, guaranteeing compliance with environmental regulations and safety standards during the process.

What Are the Common Defects Found in Aluminum Castings?

Standard defects in aluminum castings include porosity, shrinkage, misruns, cold shuts, and surface imperfections. These problems frequently occur from inadequate melting temperatures, valuable guide insufficient mold design, or poor metal flow, influencing the final casting's quality and strength.

How Do Foundries Integrate Aluminum Recycling?

Foundries integrate aluminum recycling by collecting and processing scrap aluminum, melting it, and reusing it in production. This practice reduces material costs, conserves energy, and minimizes environmental impact, promoting sustainability in manufacturing.

What Certification Requirements Exist for Those Working in Aluminum Foundries?

Aluminum foundry operators typically require certifications in metallurgy, safety protocols, and equipment operation. Standard industry certifications, including those from the American Foundry Society, ensure conformity to standards and boost operational efficiency and safety in foundries.